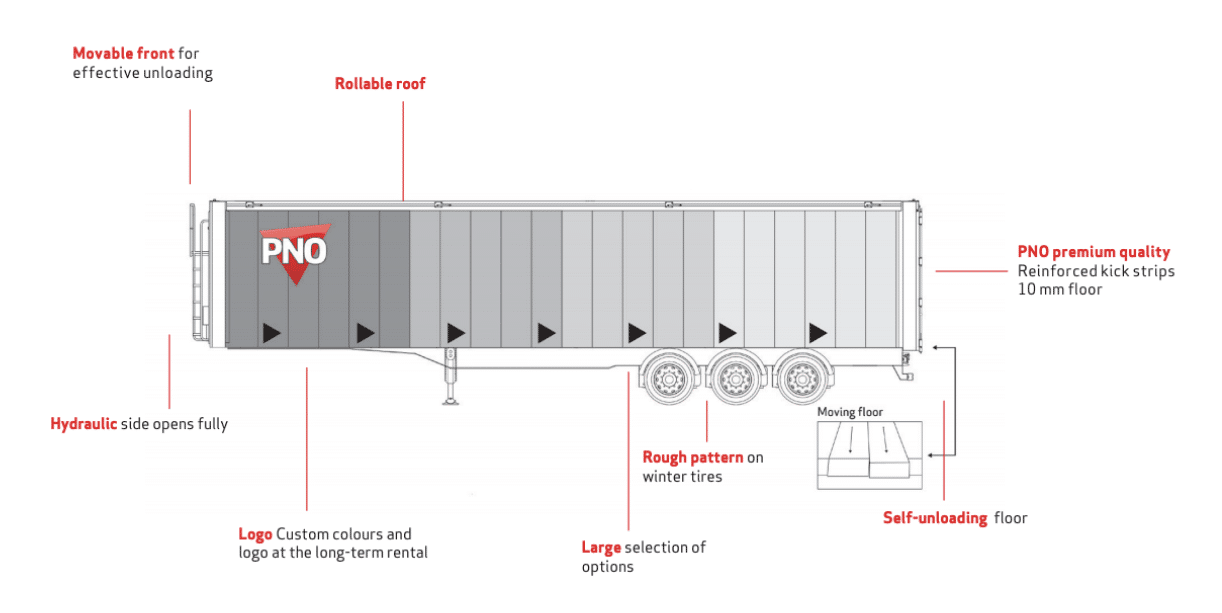

Moving Floor trailers uncovered

CONVENIENCE of MOVING FLOOR TRAILERS

Moving floor trailers make it easier to transport bulk in combination with large quantities of packaged goods. The main benefit comes when unloading bulk material from the top loaded trailer. The hydraulically controlled floor (moving or walking floor®) operates the load outwards, while the driver checks it from a safe distance. Additionally, when the trailer is loaded, the automatic sheeting systems protect the load from all weather conditions.

The semi-trailer may also optionally include a movable front wall with a rubber flap at the bottom extending onto the floor. During unloading of loose material, either of these will ensure that nothing is left behind.

It takes about 5 to 15 minutes to unload a full 13.6-metre trailer, taking less manpower, equipment and time than without the system. It is also possible to handle a full-width or full-length pallets, without opening the sides of the trailer.

PNO provides Moving Floor trailers with closed side walls but also opening side. Both opening sides with doors and fully hydraulic opening for easier loading of goods.

HOW DOES A MOVING FLOOR TRAILER OPERATE?

The hydraulically controlled floor has a number of groupings of three strips of metal, or slats. The established standard of the total number of floor slats is 21. Every third slat is connected together, hydraulically powered to move forward and backward either in unison, or alternately. When all three sets move in unison, the load is moved upon them in the direction the operator wishes.

When unloading the cargo, the entire floor moves backwards. This first “stroke” ensures that the rear part of the load falls out of the moving floor trailer. Then the slats of each group retreat in turn. Because two-thirds of the floor remains still during retraction, the load remains in place during these three strokes. Then the system is back at the end and will bump out the next part of the cargo. To better understand how the system works, watch the video below.

In need of a moving floor trailer ?

Have a look at our rental platform to see what’s currently available at PNO for short period rentals.

To rent moving floor trailers for the long-term, please contact directly your local PNO office .