Tires’ impact on People, Planet & Profit

The tire strategy of a fleet has major effects on both environment, operational costs, and safety. By embracing new technologies and improving processes, time, money, and CO2 emission can be saved.

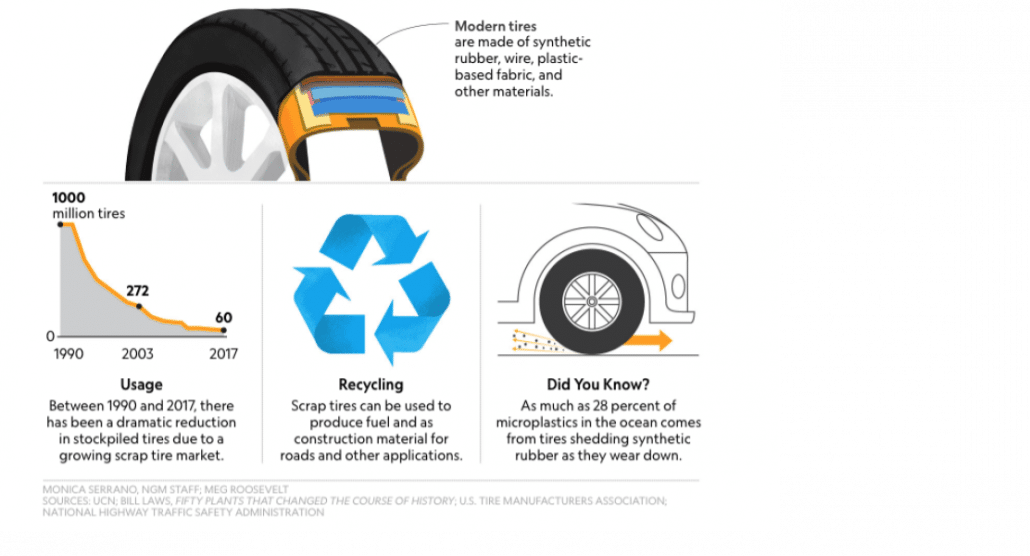

From production to disposal

Truck and trailer’s tires have a big environmental impact from production to disposal. It takes approximately 83 liters of diesel to produce the synthetic rubber used for one modern tire. If disposed through incineration, 110 kg of CO2 is emitted per tire. Tires are further one of the largest contributors to the growing amount of microplastics found in our oceans due to the shredding of synthetic rubber when they wear down.

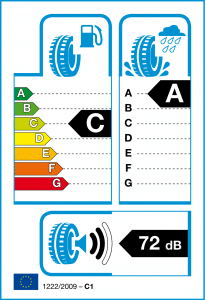

Besides examining your tire suppliers’ production and ensuring responsible disposal of worn out tires, a great way to save cost and CO2 emission is to get the most out of the tires’ operational life. Due to efficiency, investments in high quality tires with environmental benefits can compensate for some of the financial and environmental impact from its production. Environmentally friendly tires have a lower rolling resistance than standard tires, which leads to reduced fuel consumption and, hence, carbon dioxide emission. The Tire Label is one of the certifications indicating the tires rolling efficiency.

Looking into tire durability based on your operation’s context – such as main road types, weather conditions, transport type (intermodal, accompanied by ferries etc.), and driving speed – further help you find cost effective solutions.

Maintenance done right

Making sure you get the most out of a tire also means to maintain it correctly. Not only does a well-maintained tire last longer and save you the cost of a new tire, but it also increases your fleet’s uptime – a key performance indicator for all fleet managers.

Tire failures are further one of the main causes of accidents. Incorrect tire pressure and uneven wear lead to accidents to the risk of the driver and other road users’ safety. Tire pressure is a key factor in both safety and avoiding roadside breakdowns – 80% of tire blowout are caused by wrong inflation.

It is impossible to completely eliminate the costs of downtime, as accidents and breakdowns are inevitable, but through well planned maintenance you can reduce it. Technology can assist you by making your workflows smarter and increasing transparency. PNO offers the Fleet Platform, which provides automated MOT scheduling, improved trailer inspections through our Driver App & Depot Platform, and tire reports. These data keep you updated and help you manage your trailer fleet proactively to the benefit of People, Planet & Profit.

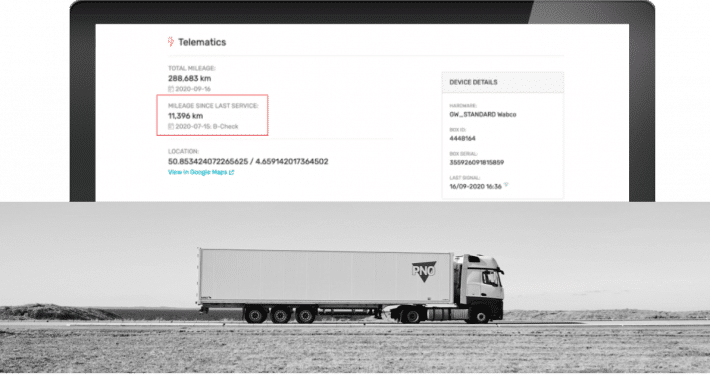

A telematic future

Telematics on trailers is not a new thing, but so far the focus has often been on GPS and tracking of trailer location. However, telematics does offer much more and the field is experiencing rapid development. Most aspects of a trailer’s condition can be tracked through the technology and it enables vital information to reach the people who need to know it easily and efficiently. Examples of what can be tracked are inside and outside temperatures, loading and unloading events, driving speed, mileage and braking patterns. Tire pressure is further possible to track and some solutions even adjust inflation automatically on the road. There are more complex solutions under development that will provide more detailed information on tire conditions.

Contact your local PNO office if you are interested in learning more about what telematic solutions we are offering.