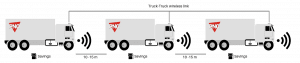

Truck Platooning: the future of road transport?

Truck Platooning: the future of road transport?

Platooning is an emerging vehicle technology through which digitally tethered convoys of two or more trucks travel closely together. Although this new solution doesn’t come without challenges, reduced fuel consumption and increased safety are just two of its multiple benefits.

What is truck platooning?

Truck platooning allows two or more trucks travel together in convoys, through connectivity technology and automated driving support systems. These vehicles automatically maintain a set, close distance between each other when they are connected for certain parts of a journey, for instance on highways. The trucks can be as close as 12 meters from each other. The truck at the head of the platoon acts as the leader, with the vehicles behind reacting and adapting to changes in its movement – requiring little to no action from drivers. Initially, drivers will remain in control at all times, so they can also decide to leave the platoon and drive independently.

Benefits

Truck platooning holds great potential to make road transport safer, cleaner and more efficient in the future. That’s why many stakeholders, including trucking manufacturers, fleet operators, academic institutions and government bodies, see the benefits of perfecting platooning practices and have been testing this technology on the roads.

Clean

Truck platooning lowers fuel consumption and CO2 emissions. Given that trucks can drive closer together, the air-drag friction is reduced significantly. Peloton Technology, the leading proponent of platooning-model, claims savings of 7% from platooning – 4.5% for the lead truck, and 10% for the following truck.

Safe

Truck platooning helps to improve safety. The tight formation reacts quickly to potential obstacles. Braking is automatic and immediate; the trucks following the lead vehicle only need one-fifth of the time a human would need to react.

Efficient

Platooning optimises transport by using roads more effectively, delivering goods faster and reducing traffic congestion. The driving range of trucks can also be extended in certain situations. Making the use of autonomous trucks easier, platooning technology could also contribute in addressing the shortage of truck drivers currently affecting the European market

Challenges

As any other emerging technology, also platooning doesn’t come without any challenges and uncertainties.

Different Truck Loads

If the loaded weight of the truck or the engine power differs too much, some might not keep up with the convoy, and others might have to brake and accelerate too many times, in order to still be more fuel efficient than without the platoon.

In addition, when the lead truck applies its brakes or accelerates, the different trucks connected in the platoon must do the same thing nearly simultaneously. For instance, a Class 8 truck carrying 40,000 pounds needs to brake or accelerate harder than a truck carrying 20,000 pounds to exactly match the speed of the truck in front of it.

Weather Conditions

Currently the technology does not perform well in rain or snow. As tires deteriorate over time, it is quite difficult to predict how they will react in a hard-braking situation.

Truck Brands

The implementation of platooning technology becomes even more difficult when different brands of trucks are used. Despite this, Peloton Technology claims their platooning system is inter-operable across different brands of trucks.

Not all manufacturers of trucks are willing to invest in this new solution. After some testing, Daimler’s Global Truck and Bus business division discovered platooning fuel economy benefits were not “as hoped” when using recent highly aerodynamic trucks and trailers. The company has therefore stopped researching into this technology.

However, the future is currently moving towards a more digitized road freight network and an advanced inter-communication between trucks as well as all other vehicles on the road. That’s why, despite the difficulties, platooning still sounds appealing and many companies – like Volvo and Scania – are making significant investments on it.

Video: “Platooning explained” by Peloton Technology