The route to a zero-emission fleet

Trucks account for approximately 2% of the vehicles on the European roads. Those 2% of vehicles are responsible for 22% of the CO2 emissions from land-based transport. The growing demand for transportation services suggests that emissions will even increase in the future; from around 2.5 Gigatonnes today to 4.6 Gigatonnes by 2050.

It is therefore key that new sustainable fleet solutions are being introduced and integrated into operational processes, so the sector can continue its growth while reducing its environmental footprint. The development of new technologies and products enabling greener transport & logistics is progressing rapidly and zero-emission fleets will be soon a reality.

Electric trucks

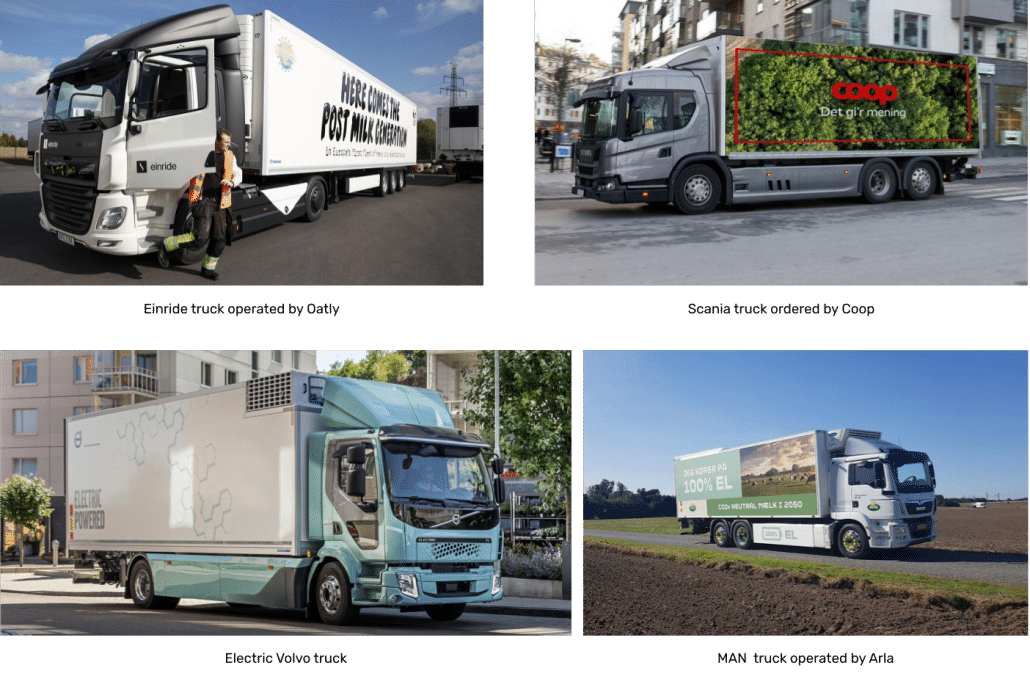

The market of electric trucks is growing fast this year with both new players and established OEMs going electric. Large global transport companies DHL, Amazon, UPS and FedEx have already invested in electric trucks to decrease their carbon footprint. In Scandinavia, companies such as Arla, Lidl, Oatly and Coop have also ordered electric trucks to add to their fleet. The Swedish industry media Dagens Logistic predicts that in 2030 half of all national trucks will be electric.

At the moment there are limitations to the use of electric trucks for longer hauls due to the battery range. Large batteries are required (typically 5-10 times the size of the largest batteries used in electric cars and 10-20 times the average car battery), which increases the vehicle weight dramatically and reduces payload capacity. With the fast development and heavy investment within EV technologies, solutions to battery size, price and range are on the horizon. Electric powered trucks are predicted by many to be the future of sustainable transport and the adoption of the technology is expected to rise significantly after 2025 when it has matured. An alternative solution to more powerful batteries is the instalments of electric wires at highways, which can power the trucks on the longer hauls. These e-highways are being tested in Sweden, Germany and Italy,

Overhead charging wires at e-highway

Hydrogen fuel cell trucks

Fuel cells generate electricity for the truck’s motors through the chemical combination of stored hydrogen and atmospheric oxygen – the process only emits water vapor. For the technology to be green, it is however necessary to use renewable energy sources to produce hydrogen.

Toyota announced in October they are bringing a Class 8 fuel cell electric truck to the North American market, in addition to their launch in Japan. The first vehicles will be ready in the first half of 2021. Hyundai already has a mass-produced hydro cell powered truck on the market and shipped the first 10 units to Europe this summer. The 10 trucks were delivered to Switzerland where they are rented on a pay-per-use basis that provides the operator with a flat rate and no risks. Nikola Motors is a well known start-up, whose hydrogen-powered trucks have already been ordered in big numbers. At the moment, the start-up is negotiating with General Motors about a future collaboration.

Toyota Hino Fuel Cell Elctric Truck

Toyota Hino Fuel Cell Elctric Truck

Compared to electric trucks, hydrogen-fueled ones have the advantage of longer range and shorter charging time. The main issue is currently the production capacity of hydrogen cells from renewable sources and the storage of the fuel – the infrastructure needed to charge on the road is not yet implemented. Price is further a major barrier for operators, as the hydro cell trucks are very expensive at the moment. With the current price of powering with hydro cells, the trucks are much more expensive during its operational life compared to diesel trucks.

Bio-LNG

Bio-LNG (known as liquefied biogas) has been available as vehicle fuel for some time, but hasn’t caught the same attention as electric or hydro powered trucks. It does, however, offer a current alternative to diesel for the long haul transportation. Bio-LNG is a highly efficient fuel with minimal emission of CO2 and particles. The fuel can be made from feedstock, such as non-edible parts of grain, sewage and household waste, so it doesn’t compete with the food supply – something biofuels have been widely criticized for.

The two main adaptation barriers of bio-LNG have been the cost and distribution network, which haven’t been able to compete with diesel. The commercialization of the technology – that was previously mostly produced by municipalities – is driving lower cost and expansion of fueling locations. With its long operational range and fast fueling time, bio-LNG is an available solution for fleet managers, until the electric and hydro powered trucks are ready for long haul transports.

Reefer trailers

An often overseen source of emissions in heavy load transport is the operation of reefer trailers. A standard reefer trailer uses 30 liters of diesel a day and emits approximately 80 kg of CO2. If 20% of the reefers in West-Europe became CO2-neutral, it would lead to an annual saving of 19.000.000 tons of CO2. The particle emission from reefers is often relatively high as well, as the filters do not have the same high standards as on trucks and other vehicles.

PNO is offering one of the leading CO2-neutral reefer trailers on the market, the New Cool. The cooling system is powered by a special Valx axle, which produces energy while braking. No diesel and no emission of CO2, particles or noise.